selection for clamshell packaging

Sometimes customers ask which clamshell packaging material is cheaper or better for their products, in fact from our point of view there are no cheaper or better materials. The material we choose should be compatible with our products and their functions. For example, if we need a clamshell for food, we should choose PET, or if we need blister packaging for hardware, PVC is better choice.

Although PVC and PET are both clamshell and blister packaging materials, and the price of PVC is cheaper than PET, but PVC is not an environmentally friendly material, it cannot use directly for food. So if we use PVC clamshell for food, we have to make another bag packaging first and then put it into the clamshell. This is a waste of material and time. So in this situation, we should choose PET directly.

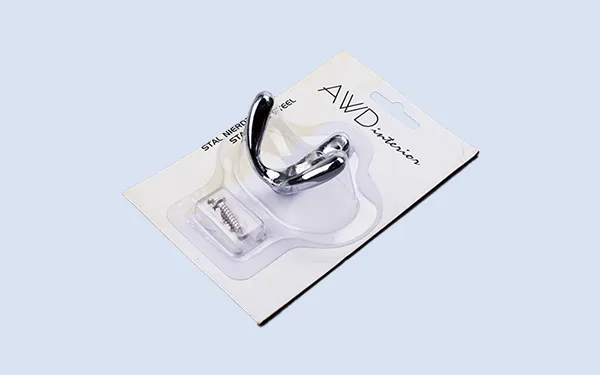

PVC is not environmentally friendly, but the cost is lower than others, it will be a good choice if we use it to the hardware tools products. PET material is environmentally friendly and anti-static material, so if customers said they need anti-static material, we recommend PET or PS.

In summary, the selection of materials for clamshell packaging must take into account product characteristics, packaging requirements, cost and other factors, the In the high-temperature environment may release harmful substances, less suitable for packaging food and other products with high safety requirements; its waste in the natural environment is difficult to degrade, a certain degree of environmental pollution.are some common clamshell packaging materials and their characteristics, so that you can choose according to the actual situation:

Material options for clamshell packaging

PVC

Advantages:

- Good transparency and gloss, it can clearly show the product to customers.

- It has a soft texture and some flexibility, making it good for odd-shaped items

- It is easy to mold into different shapes

- Chemical stability, resistance to acid, alkali and other chemicals;

- The cost is lower than other materials.

Disadvantages: In the high-temperature environment may release harmful substances, it’s not suitable for food packaging and other products need high safety requirements. PVC waste does not break down easily, it may cause environmental pollution.

Applicable: Toys, Stationery, Cosmetics, Electronic accessories and other products.

PET

Advantages:

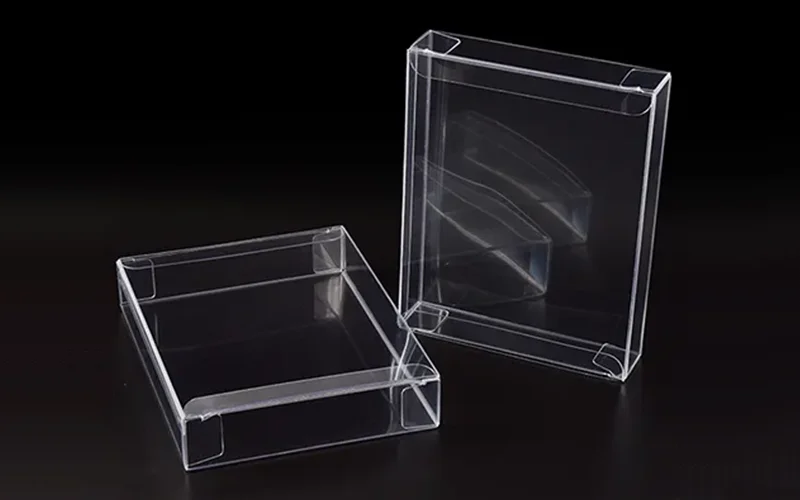

- High transparency and gloss, beautiful packaging effect, it can enhance the product quality.

- It is safe, non-toxic, and meets food safety standards.

- PET is strong and tough, protecting products well.

- It can protect the product from moisture, oxidation.

Disadvantages: PET does not handle high heat well and can deform easily. It is more expensive, raising packaging costs.

Applicable: Food, Medicine, Health Care Products, High-end Cosmetics and other products with high requirements for health and safety and packaging aesthetics packaging.

PS

Advantages:

PS is rigid and hard, keeping packaging in shape. It has a smooth surface and prints well, allowing for attractive designs. It is also cost-effective.

Disadvantages: Brittle, easy to break; poor impact resistance, easy to be damaged when hit by external forces; a certain degree of environmental pollution, its waste is difficult to natural degradation.

Applicable: Suitable for small electronic products, daily necessities, handicrafts and other packaging, also commonly used in the production of blister trays.

PP

Advantages:

PP can handle high heat without deforming. It resists many chemicals and is lightweight, reducing packaging weight. It is also non-toxic and meets food safety standards.

Disadvantages: Low transparency, not as good as PVC and PET; easily brittle at low temperatures, reduced toughness.

Applicable: Commonly used in food packaging, pharmaceutical packaging and some products requiring high temperature sterilisation packaging.